| Product Code : |

APC-SG-PT062 |

|---|

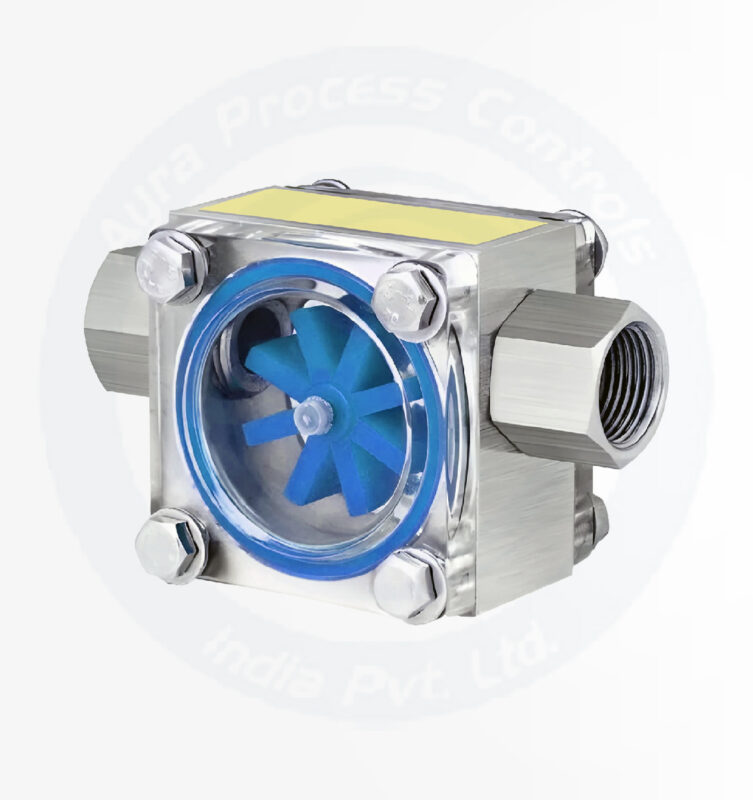

Pad Type Sight Glass

The Pad Type Sight Glass is a compact and durable visual flow indicator designed for direct mounting on tanks, vessels, or pipelines. It enables operators to observe the internal process without interrupting operations. Its low-profile design, combined with robust construction, makes it suitable for industries like pharmaceuticals, chemicals, food and beverage, and petrochemicals.

Specification | Details |

|---|---|

Size Range | 1” to 16” |

Pressure Rating | Up to 10 bar |

Connection | Flanged ANSI B16.5, 150#RF |

Window Material | Borosilicate Glass |

Material | Stainless Steel (SS304, SS316) Carbon Steel |

Features

- Compact Design: Ideal for tight spaces and direct installation on tanks or pipelines.

- Robust Construction: Handles high pressure and temperature conditions effectively.

- Clear Observation: Provides unobstructed visibility of the process medium.

- Corrosion Resistance: Built to withstand aggressive chemicals and harsh media.

- Easy Installation: Simple and secure mounting with minimal maintenance.

- Leak-Proof Seal: Ensures safe and efficient operation even under challenging conditions.

Applications

- Tanks & Vessels: Used for monitoring the level and flow of liquids inside storage tanks.

- Chemical Processing: Ideal for corrosive and hazardous fluid observation.

- Food & Beverage: Ensures flow visibility while maintaining hygiene standards.

- Pharmaceuticals: Facilitates sterile process observation in manufacturing.

- Petrochemicals: Suitable for observing oil, gas, and other hydrocarbons in processing units.

- Compact Design: Ideal for tight spaces and direct installation on tanks or pipelines.

- Robust Construction: Handles high pressure and temperature conditions effectively.

- Clear Observation: Provides unobstructed visibility of the process medium.

- Corrosion Resistance: Built to withstand aggressive chemicals and harsh media.

- Easy Installation: Simple and secure mounting with minimal maintenance.

- Leak-Proof Seal: Ensures safe and efficient operation even under challenging conditions.

- Tanks & Vessels: Used for monitoring the level and flow of liquids inside storage tanks.

- Chemical Processing: Ideal for corrosive and hazardous fluid observation.

- Food & Beverage: Ensures flow visibility while maintaining hygiene standards.

- Pharmaceuticals: Facilitates sterile process observation in manufacturing.

- Petrochemicals: Suitable for observing oil, gas, and other hydrocarbons in processing units.