| Product Code : |

APC-SG-DW057 |

|---|

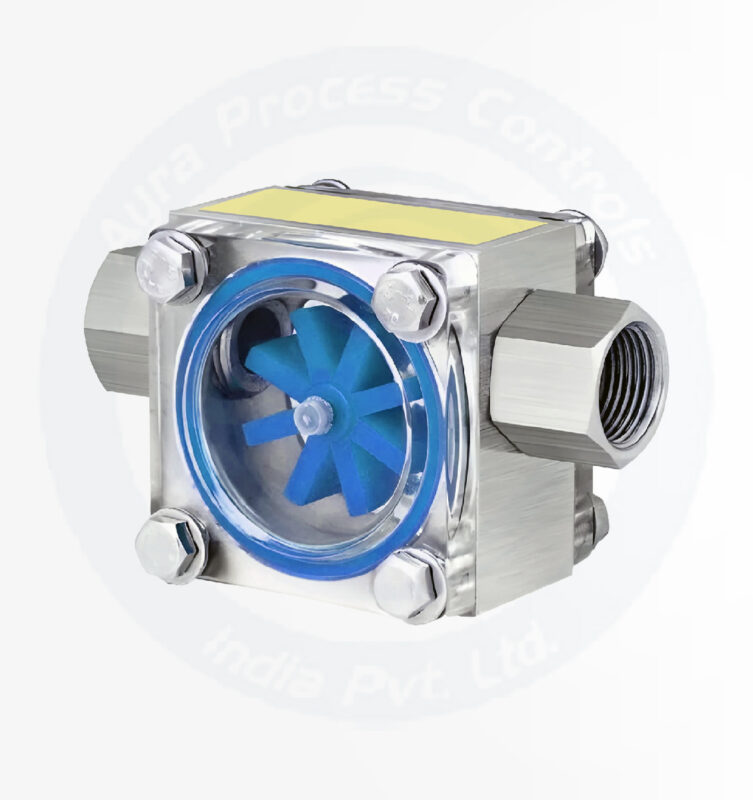

Double Window Sight Glass

The Double Window Sight Glass is a robust device designed for visually monitoring the flow of liquids and gases in pipelines. It features two parallel viewing windows, allowing operators to inspect the medium without disrupting the process. This device is widely used in industries like chemical processing, pharmaceuticals, food and beverage, and water treatment, where process visibility is essential for quality control and safety.

Specification | Details |

|---|---|

Size Range | Upto 400 NB |

Pressure Rating | Up to 20 bar |

Connection | Flanged ANSI B16.5, 150#RF |

Window Material | Borosilicate Glass, Tempered Glass |

Material | CI/ASTMA 216/ GRWCB/ASTMA 351 CF8/ASTMA 351F8M/MS/GS |

Features

- Double Window Design: Provides clear visibility of the process medium from both sides.

- Durable Construction: Made with high-grade materials to handle high pressure and temperature.

- Chemical Resistance: Suitable for corrosive and non-corrosive media.

- Leak-Proof Seal: Ensures no leakage through the windows.

- Low Maintenance: Designed for long-lasting use with minimal upkeep.

- Easy Installation: Compatible with various pipeline systems and connection types.

Applications

- Chemical Industry: Monitors corrosive fluids and ensures process safety.

- Pharmaceuticals: Ensures visual inspection of clean fluids during production.

- Food and Beverage: Monitors product flow to maintain quality standards.

- Water Treatment: Checks fluid clarity and flow in pipelines.

- Oil and Gas: Used in refineries for monitoring oil and gas flow.

- Power Plants: Ensures visibility of coolant or steam in pipelines.

- Double Window Design: Provides clear visibility of the process medium from both sides.

- Durable Construction: Made with high-grade materials to handle high pressure and temperature.

- Chemical Resistance: Suitable for corrosive and non-corrosive media.

- Leak-Proof Seal: Ensures no leakage through the windows.

- Low Maintenance: Designed for long-lasting use with minimal upkeep.

- Easy Installation: Compatible with various pipeline systems and connection types.

- Chemical Industry: Monitors corrosive fluids and ensures process safety.

- Pharmaceuticals: Ensures visual inspection of clean fluids during production.

- Food and Beverage: Monitors product flow to maintain quality standards.

- Water Treatment: Checks fluid clarity and flow in pipelines.

- Oil and Gas: Used in refineries for monitoring oil and gas flow.

- Power Plants: Ensures visibility of coolant or steam in pipelines.