| Product Code : |

APC-ST-YTS051 |

|---|

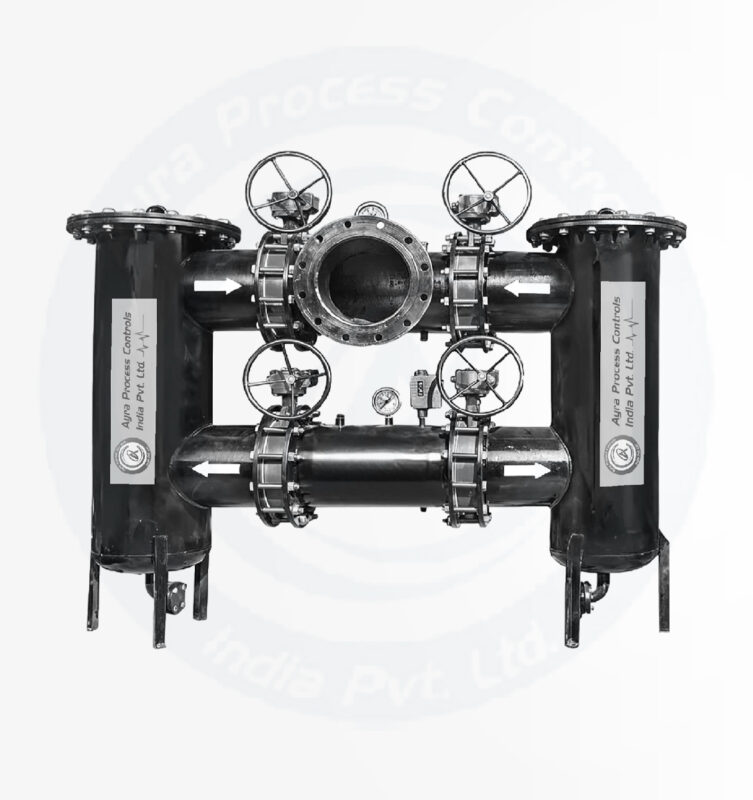

Y Type Strainer

A Y Type Strainer is a compact and efficient filtration device used to remove debris, solids, and impurities from liquids, gases, or steam in pipelines. Its Y-shaped design allows the strainer to handle high-pressure and high-temperature applications while ensuring smooth flow and protecting downstream equipment like pumps, valves, and meters. The Y Type Strainer is commonly used in industries such as water treatment, oil and gas, chemical processing, and power generation.

Specification | Details |

|---|---|

Size Range | 4 NB TO 400 NB |

Connection | Flanged / Screwed / ButtWeld |

Body Material | CI/ASTMA 216 GRWCB/ ASTMA 351 CF8/ ASTMA 351 F8M/ MS/CS /SS304/ SS304L/SS316/ SS316L |

Features

- Durable Construction: Built to withstand high-pressure and temperature conditions.

- Compact Design: Space-saving Y-shaped configuration for easy installation.

- Easy Maintenance: Includes a blow-off or drain plug for quick cleaning of the strainer.

- Customizable Options: Available in various materials, sizes, and mesh types.

- Corrosion-Resistant Materials: Ensures a long service life even in harsh environments.

- Versatile Applications: Suitable for liquids, gases, and steam.

Applications

- Water Treatment Plants: Filters debris from water before distribution.

- Oil and Gas Pipelines: Protects equipment by removing solid impurities.

- Chemical Processing: Ensures clean fluids for precise chemical reactions.

- Power Plants: Filters contaminants from boiler feed water and steam.

- Pharmaceuticals: Ensures the purity of process fluids.

- HVAC Systems: Removes debris from cooling and heating systems.

- Durable Construction: Built to withstand high-pressure and temperature conditions.

- Compact Design: Space-saving Y-shaped configuration for easy installation.

- Easy Maintenance: Includes a blow-off or drain plug for quick cleaning of the strainer.

- Customizable Options: Available in various materials, sizes, and mesh types.

- Corrosion-Resistant Materials: Ensures a long service life even in harsh environments.

- Versatile Applications: Suitable for liquids, gases, and steam.

- Water Treatment Plants: Filters debris from water before distribution.

- Oil and Gas Pipelines: Protects equipment by removing solid impurities.

- Chemical Processing: Ensures clean fluids for precise chemical reactions.

- Power Plants: Filters contaminants from boiler feed water and steam.

- Pharmaceuticals: Ensures the purity of process fluids.

- HVAC Systems: Removes debris from cooling and heating systems.