| Product Code : |

APC-ST-TTS053 |

|---|

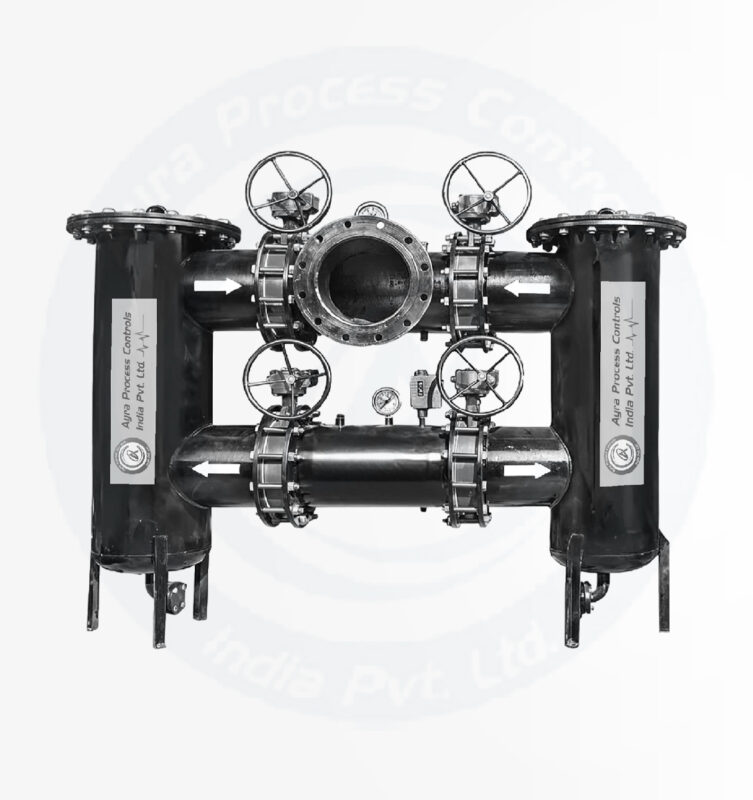

Tee Type Strainer

A Tee Type Strainer is a compact and efficient filtration device designed to remove debris, solids, and impurities from fluids in pipelines. It is called a “Tee” type due to its T-shaped configuration, making it an ideal choice for applications with limited space and where inline filtration is required. Tee Type Strainers are commonly used in industries like oil and gas, water treatment, chemical processing, and power generation to protect pumps, valves, and other downstream equipment.

Specification | Details |

|---|---|

Size Range | 2” to 24” |

Pressure Rating | ANSI Class 150, 300 |

Filtration Rating | 50 to 1000 microns |

Body Material | Carbon Steel, Stainless Steel (SS304, SS316) |

Features

- T-Shaped Design: Compact structure for easy inline installation.

- Efficient Filtration: Removes impurities and debris effectively.

- Durable Construction: Built to handle high pressures and temperatures.

- Easy Maintenance: Quick access for cleaning or replacing the strainer element.

- Customizable Options: Available in various materials, sizes, and filtration ratings.

- Corrosion Resistance: Ensures a long service life in harsh conditions.

Applications

- Water Treatment Plants: Removes debris from raw water and ensures clean water flow.

- Oil and Gas Industry: Protects pipelines and equipment from solid contaminants.

- Chemical Processing: Maintains clean process fluids for sensitive operations.

- Power Plants: Filters boiler feed water and steam to prevent equipment damage.

- Pharmaceuticals: Ensures the purity of process fluids and water.

- HVAC Systems: Protects cooling and heating systems by removing impurities.

- T-Shaped Design: Compact structure for easy inline installation.

- Efficient Filtration: Removes impurities and debris effectively.

- Durable Construction: Built to handle high pressures and temperatures.

- Easy Maintenance: Quick access for cleaning or replacing the strainer element.

- Customizable Options: Available in various materials, sizes, and filtration ratings.

- Corrosion Resistance: Ensures a long service life in harsh conditions.

- Water Treatment Plants: Removes debris from raw water and ensures clean water flow.

- Oil and Gas Industry: Protects pipelines and equipment from solid contaminants.

- Chemical Processing: Maintains clean process fluids for sensitive operations.

- Power Plants: Filters boiler feed water and steam to prevent equipment damage.

- Pharmaceuticals: Ensures the purity of process fluids and water.

- HVAC Systems: Protects cooling and heating systems by removing impurities.