| Product Code : |

APC-ST-SCS046 |

|---|

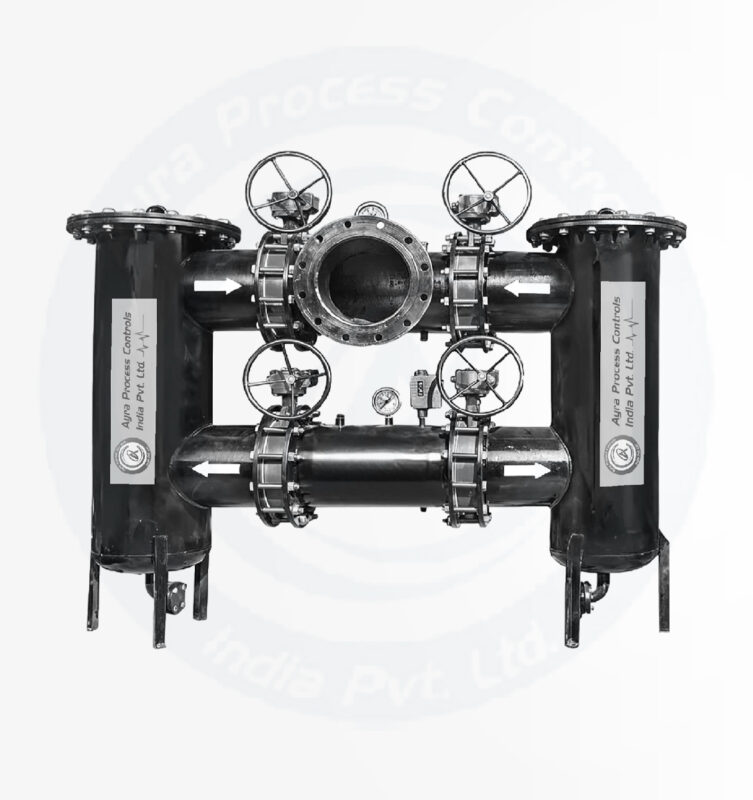

Self-Cleaning Strainer

A Self-Cleaning Strainer is an advanced filtration device designed to continuously remove debris and solid particles from liquids without interrupting the flow or requiring manual cleaning. It is highly efficient and cost-effective, reducing maintenance downtime while ensuring uninterrupted system performance. These strainers are widely used in industries like water treatment, oil and gas, chemical processing, food and beverage, and power generation.

Specification | Details |

|---|---|

Size Range | 1” to 24” |

Body Material | Stainless Steel (SS304, SS316), Carbon Steel |

Pressure Rating | 25 to 1000 microns |

Filtration Rating | Up to 10 bar |

Features

- Automatic Cleaning Mechanism: Continuously cleans the filter element without manual intervention.

- Uninterrupted Flow: No need to shut down operations during cleaning.

- Efficient Filtration: Handles high levels of solids and provides consistent performance.

- Durable Construction: Built to withstand high pressures and harsh environments.

- Customizable Options: Available in various materials, sizes, and filtration levels.

Applications

- Water Treatment Plants: Removes debris from raw water and cooling water.

- Oil and Gas: Filters contaminants in pipeline systems and offshore platforms.

- Chemical Processing: Ensures clean fluids for critical processes.

- Food and Beverage: Provides hygienic filtration in production lines.

- Power Generation: Protects equipment in cooling water and condensate systems.

- Irrigation Systems: Prevents clogging in drip and sprinkler systems.

- Automatic Cleaning Mechanism: Continuously cleans the filter element without manual intervention.

- Uninterrupted Flow: No need to shut down operations during cleaning.

- Efficient Filtration: Handles high levels of solids and provides consistent performance.

- Durable Construction: Built to withstand high pressures and harsh environments.

- Customizable Options: Available in various materials, sizes, and filtration levels.

- Water Treatment Plants: Removes debris from raw water and cooling water.

- Oil and Gas: Filters contaminants in pipeline systems and offshore platforms.

- Chemical Processing: Ensures clean fluids for critical processes.

- Food and Beverage: Provides hygienic filtration in production lines.

- Power Generation: Protects equipment in cooling water and condensate systems.

- Irrigation Systems: Prevents clogging in drip and sprinkler systems.