| Product Code : |

APC-ST-DSBV047 |

|---|

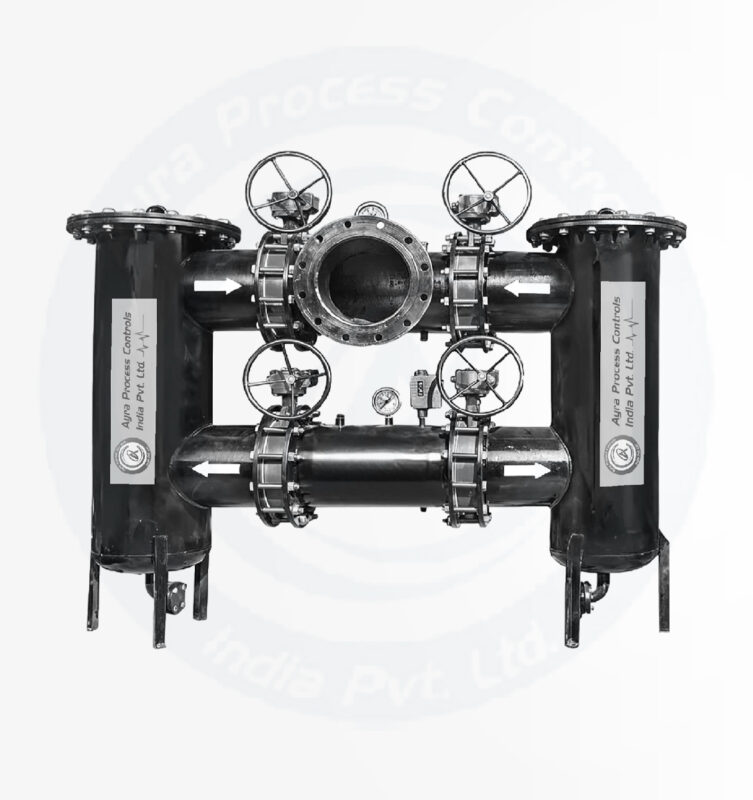

Duplex Strainer with Butterfly Valve

A Duplex Strainer with Butterfly Valve is a dual-chamber filtration system that allows uninterrupted operation by enabling one chamber to be cleaned while the other continues filtering. Equipped with butterfly valves for smooth switching between chambers, this system ensures continuous flow and optimal filtration, making it ideal for industries that cannot afford downtime. It is widely used in applications like water treatment, chemical processing, oil and gas, and power generation.

Specification | Details |

|---|---|

Size Range | 2” to 20” |

Body Material | Stainless Steel (SS304, SS316), Carbon Steel |

Pressure Rating | 25 to 1000 microns |

Filtration Rating | Up to 16 bar |

Features

- Continuous Operation: One chamber remains operational while the other is cleaned.

- Butterfly Valves: Easy and reliable chamber switching for maintenance.

- High Filtration Efficiency: Effectively removes particles and debris from fluids.

- Rugged Design: Built to withstand high pressures and corrosive environments.

- Customizable Options: Available in various materials, sizes, and filtration levels.

- Easy Maintenance: Simplifies cleaning and reduces downtime.

Applications

- Water Treatment Plants: Removes particles from raw and treated water.

- Oil and Gas: Filters contaminants in pipelines and offshore platforms.

- Chemical Processing: Protects sensitive equipment by ensuring clean fluid flow.

- Power Plants: Used in cooling water and boiler feed systems.

- Pharmaceuticals: Provides clean process fluids for critical operations.

- Marine Industry: Filters seawater and other fluids for ship systems.

- Continuous Operation: One chamber remains operational while the other is cleaned.

- Butterfly Valves: Easy and reliable chamber switching for maintenance.

- High Filtration Efficiency: Effectively removes particles and debris from fluids.

- Rugged Design: Built to withstand high pressures and corrosive environments.

- Customizable Options: Available in various materials, sizes, and filtration levels.

- Easy Maintenance: Simplifies cleaning and reduces downtime.

- Water Treatment Plants: Removes particles from raw and treated water.

- Oil and Gas: Filters contaminants in pipelines and offshore platforms.

- Chemical Processing: Protects sensitive equipment by ensuring clean fluid flow.

- Power Plants: Used in cooling water and boiler feed systems.

- Pharmaceuticals: Provides clean process fluids for critical operations.

- Marine Industry: Filters seawater and other fluids for ship systems.