| Product Code : |

APC-ST-BTS045 |

|---|

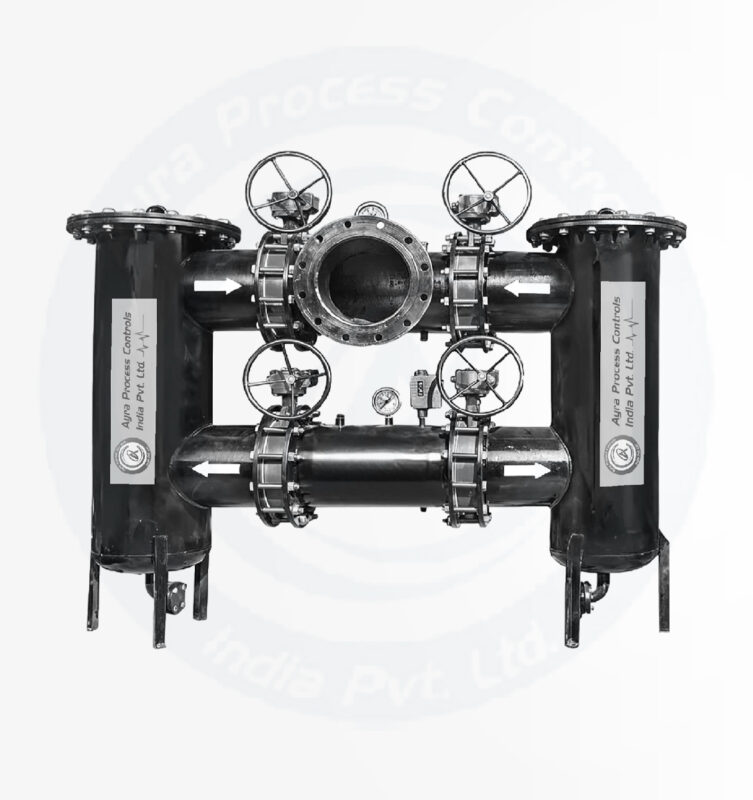

Basket Type Strainer

A Basket Type Strainer is a vital component in fluid systems designed to filter and remove debris, dirt, and other unwanted particles from liquids, gases, or steam. With its high dirt-holding capacity and easy maintenance, the basket strainer ensures smooth operation and prevents damage to downstream equipment like pumps, valves, and pipelines. It is widely used in industries such as oil and gas, chemical processing, power generation, water treatment, and more.

Specification | Details |

|---|---|

Size Range | Upto 1200 NB |

Body Material | MS/CS/SS304/SS304L/SS316/SS316L |

End Connections | Flanged/Buttweld |

Features

- Efficient Filtration: Removes debris and solid particles effectively.

- High Dirt-Holding Capacity: Reduces the frequency of cleaning and maintenance.

- Durable Design: Built to handle high pressures and temperatures.

- Customizable Mesh Size: Filters can be tailored to specific filtration needs.

- Easy Maintenance: Quick removal of the basket for cleaning or replacement.

- Standards Compliance: Designed as per ASME, DIN, or API standards.

Applications

- Oil and Gas: Filters contaminants in pipelines to protect pumps and valves.

- Chemical Processing: Ensures the purity of liquids and protects sensitive equipment.

- Power Plants: Removes debris from cooling water and boiler feed systems.

- Water Treatment: Filters solids in filtration and distribution systems.

- Pharmaceuticals: Provides clean and particle-free fluids in sensitive processes.

- Efficient Filtration: Removes debris and solid particles effectively.

- High Dirt-Holding Capacity: Reduces the frequency of cleaning and maintenance.

- Durable Design: Built to handle high pressures and temperatures.

- Customizable Mesh Size: Filters can be tailored to specific filtration needs.

- Easy Maintenance: Quick removal of the basket for cleaning or replacement.

- Standards Compliance: Designed as per ASME, DIN, or API standards.

- Oil and Gas: Filters contaminants in pipelines to protect pumps and valves.

- Chemical Processing: Ensures the purity of liquids and protects sensitive equipment.

- Power Plants: Removes debris from cooling water and boiler feed systems.

- Water Treatment: Filters solids in filtration and distribution systems.

- Pharmaceuticals: Provides clean and particle-free fluids in sensitive processes.