| Product Code : |

APC-SG-RT063 |

|---|

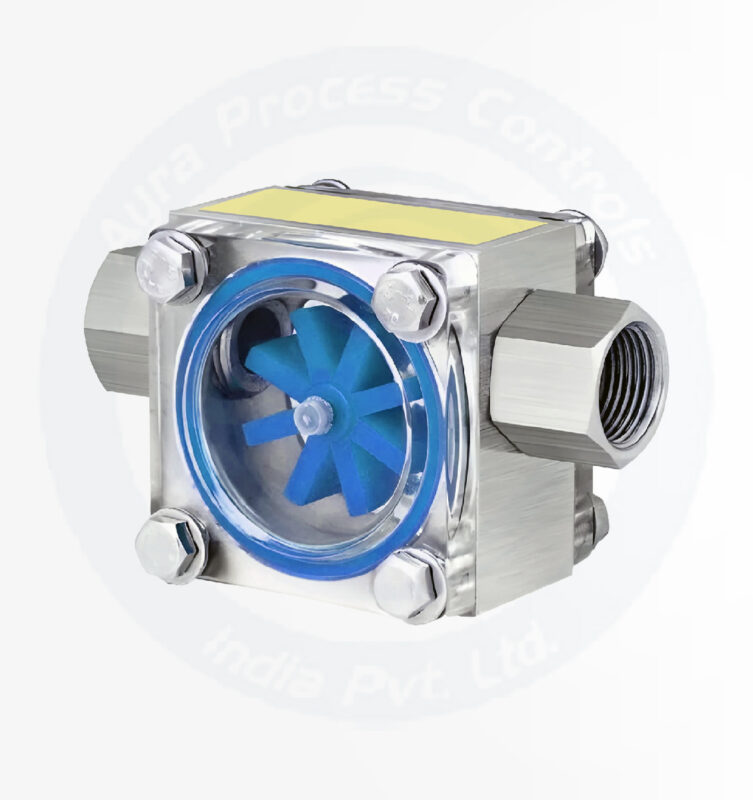

Rectangular Sight Glass

The Rectangular Sight Glass is a specialized visual inspection device designed to provide clear visibility of fluid flow or process conditions in pipelines, tanks, and vessels. Its rectangular design offers a broader viewing area, making it ideal for monitoring processes in industries like chemical processing, food and beverage, pharmaceuticals, and water treatment.

Specification | Details |

|---|---|

Size Range | 4” x 6” to 24” x 36” |

Pressure Rating | Up to 16 bar |

Connection | Flanged ANSI B16.5, 150#RF |

Window Material | Borosilicate Glass |

Material | Stainless Steel (SS304, SS316) Carbon Steel |

Features

- Wide Viewing Area: The rectangular design provides an expanded field of vision for better observation.

- Robust Construction: Built to withstand high pressures and temperatures.

- Corrosion Resistance: Suitable for aggressive and non-aggressive process media.

- Leak-Proof Sealing: Ensures operational safety and efficiency.

- Customizable Design: Available in different sizes and materials to meet application needs.

- Low Maintenance: Durable design minimizes maintenance requirements.

Applications

- Chemical Industry: Real-time monitoring of corrosive and hazardous fluids.

- Pharmaceuticals: Ensures sterile process visibility in manufacturing units.

- Food & Beverage: Allows inspection of fluids in hygienic processing systems.

- Water Treatment Plants: Ideal for observing fluid movement in treatment tanks and pipelines.

- Oil & Gas: Suitable for monitoring crude oil, gas, or refined products in pipelines.

- Wide Viewing Area: The rectangular design provides an expanded field of vision for better observation.

- Robust Construction: Built to withstand high pressures and temperatures.

- Corrosion Resistance: Suitable for aggressive and non-aggressive process media.

- Leak-Proof Sealing: Ensures operational safety and efficiency.

- Customizable Design: Available in different sizes and materials to meet application needs.

- Low Maintenance: Durable design minimizes maintenance requirements.

- Chemical Industry: Real-time monitoring of corrosive and hazardous fluids.

- Pharmaceuticals: Ensures sterile process visibility in manufacturing units.

- Food & Beverage: Allows inspection of fluids in hygienic processing systems.

- Water Treatment Plants: Ideal for observing fluid movement in treatment tanks and pipelines.

- Oil & Gas: Suitable for monitoring crude oil, gas, or refined products in pipelines.