| Product Code : |

APC-SG-DWRW059 |

|---|

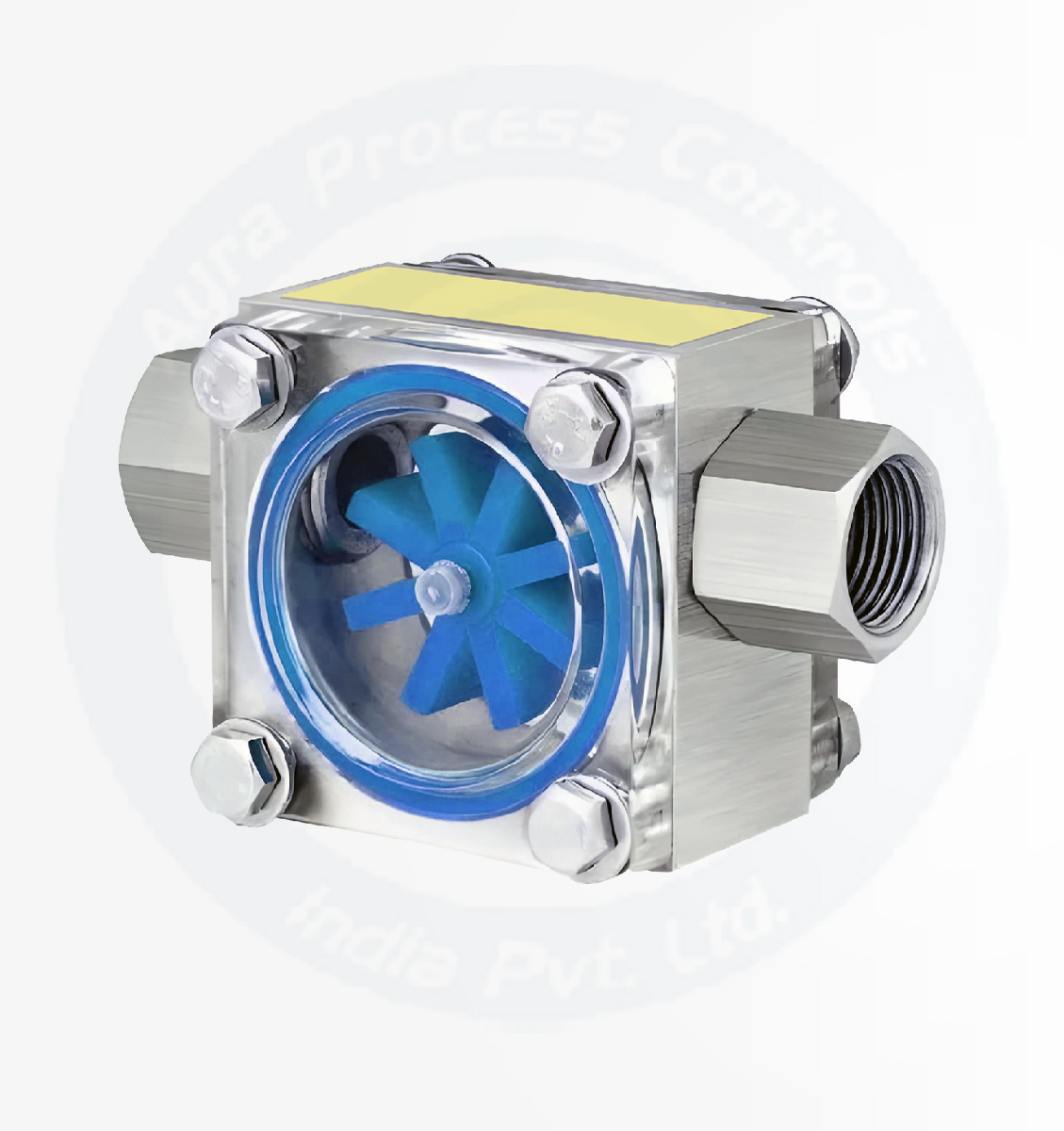

Double Window Sight Glass With Rotary Wheel

The Double Window Sight Glass with Rotary Wheel is an innovative flow monitoring device designed to provide visual confirmation of fluid movement in pipelines. This model is equipped with a rotary wheel that rotates as the fluid flows, offering a clear and dynamic indication of flow presence and rate. It is particularly suitable for industries requiring precise flow observation and enhanced operational safety.

Specification | Details |

|---|---|

Size Range | ½” to 12” |

Pressure Rating | Up to ANSI Class 300 |

Connection | Flanged or Threaded as required |

Glass Type | Toughened borosilicate or quartz |

Material | SS, CS or Other Alloys |

Features

- Rotary Wheel Mechanism: Rotates in response to fluid flow, enabling quick and easy monitoring.

- Double Window Design: Transparent viewing from both sides for optimal visibility.

- Rugged Construction: Engineered for high-pressure and high-temperature environments.

- Chemical Resistance: Suitable for aggressive or non-corrosive fluids.

- Leak-Proof Sealing: Ensures safety and reliability in critical processes.

- Low Maintenance: Designed for long-term durability with minimal upkeep.

Applications

- Process Flow Monitoring: Visually confirms flow rates in industrial pipelines.

- Chemical Processing: Ideal for monitoring aggressive fluids in chemical plants.

- Pharmaceuticals: Ensures precision flow control in sterile and hygienic environments.

- Food & Beverage: Tracks fluid movement in sanitary systems to maintain quality.

- Water Treatment Plants: Used for real-time monitoring of clean or wastewater flows.

- Oil & Gas: Suitable for monitoring flow in crude oil and gas pipelines.

- Rotary Wheel Mechanism: Rotates in response to fluid flow, enabling quick and easy monitoring.

- Double Window Design: Transparent viewing from both sides for optimal visibility.

- Rugged Construction: Engineered for high-pressure and high-temperature environments.

- Chemical Resistance: Suitable for aggressive or non-corrosive fluids.

- Leak-Proof Sealing: Ensures safety and reliability in critical processes.

- Low Maintenance: Designed for long-term durability with minimal upkeep.

- Process Flow Monitoring: Visually confirms flow rates in industrial pipelines.

- Chemical Processing: Ideal for monitoring aggressive fluids in chemical plants.

- Pharmaceuticals: Ensures precision flow control in sterile and hygienic environments.

- Food & Beverage: Tracks fluid movement in sanitary systems to maintain quality.

- Water Treatment Plants: Used for real-time monitoring of clean or wastewater flows.

- Oil & Gas: Suitable for monitoring flow in crude oil and gas pipelines.